With the continuous development of information technology, digital technology is playing an increasingly important role in different fields. The same is true in the packaging industry. With the continuous progress of domestic film Slitter technology, obvious breakthroughs have been made in speed, width, control and comprehensive performance, and digitalization has also become an important direction of domestic film Slitter development.

Before many packaging materials are used for packaging, they often go through many processes, such as slitting, printing (or coating), compounding, slitting, etc., but the cutting methods in each slitting process are different. The common cutting methods are:

(1) Cutting edge, cutting the process edge material reserved in the previous process, mostly used for the processing of composite membrane and other materials;

(2) Cutting, cutting the wide coil into multiple coils of narrow size materials;

(3) In the process of rewinding, the material with large diameter is divided into several materials with small diameter. The sliver rewinder is equivalent to rewinding and so on. These methods are sometimes used in combination. No matter which process is adopted, the cut material shall meet the corresponding technical indicators: dimension requirements (referring to the width and length of the cut material) and quality requirements (flatness of the coil, surface quality, etc.).

The manufacture and purchase of qualified slitting equipment should not only meet these technical indicators, but also consider the following two factors: operation efficiency, mainly including the working speed, stability of the equipment and the difficulty of machine operation, etc.; economic performance, refers to the scope of application of equipment to materials, processing limit size, equipment price, energy consumption, etc.

With the continuous development of packaging technology and the improvement of packaging grade, the performance requirements of packaged goods for packaging materials are increasingly prominent. There are many materials with special performance, such as aluminum-plated film with shading effect and high surface quality requirements, CPP thin film with large elongation, multi-material composite film with high barrier performance, etc. The continuous application of various new materials promotes the rapid development of soft packaging market. With the growth of market demand and the development of special application fields, the requirements of packaging material cutting are higher and higher, and the requirements of cutting equipment are more and more stringent. On the other hand, with the gradual promotion of automatic packaging equipment in the packaging industry, such as food packaging, cigarette packaging, etc., these automatic packaging machines are very picky about the quality requirements of materials after slitting, which brings a broad development space for the slitter to high-grade, high-precision control.

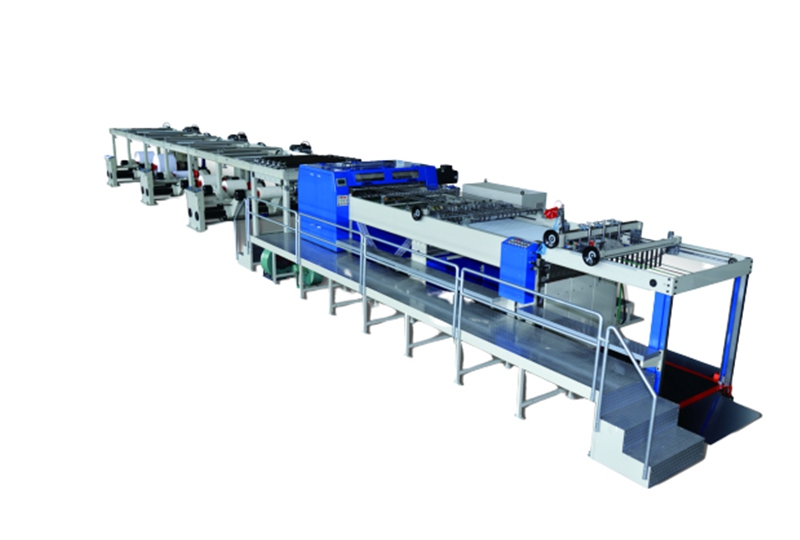

In the past, the high-precision and high-speed slitter used by domestic enterprises was mainly monopolized by a few foreign manufacturers. With regard to the development of domestic Slitter, there is an image metaphor in the industry: the early slitter has a simple structure, with a speed of about 100m / min, and the mechanical friction mode of winding tension is manual control, which people call it "telephone"; later, after some modifications, the winding is controlled by clutch, and the single motor controls traction and winding, with a speed of less than 200m / min, which is called "Analog machine"; since then, the new full-automatic high-speed cutting machine, using digital automatic control, has a speed of more than 300m / min, just like the "digital machine" in the modern communication field.